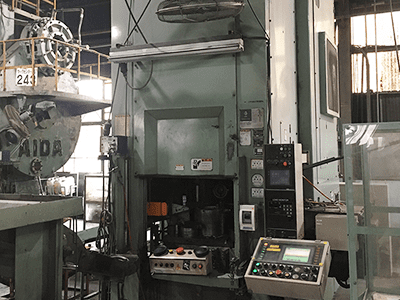

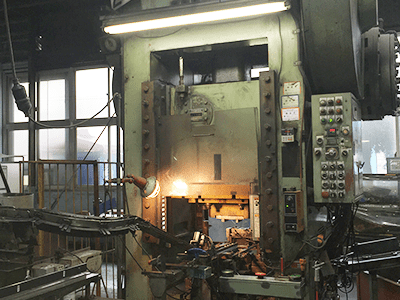

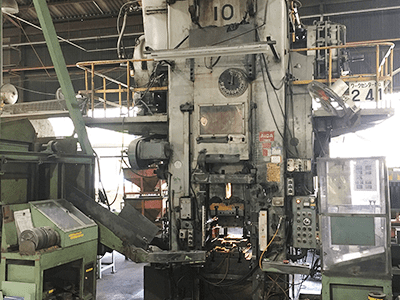

Cold forging is to press the metallic material by a press machine at room temperature without heating up the material. Merit of cold forging is its precise dimensions and smooth surface. Cold forging is suitable with automatization and we also make cold forging automatically.

As the metal flow follows the shape of a product, cold forging is excellent in terms of strength. There are various methods for cold forging, such as push out method, Getting out burrs method, sealing up method and so on. We use those methods to make cold forging for small crankshaft and gear.