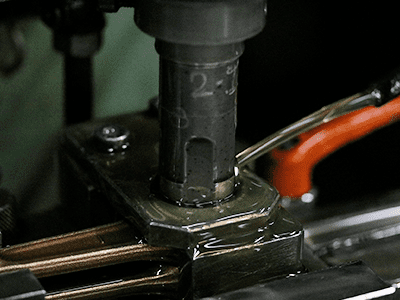

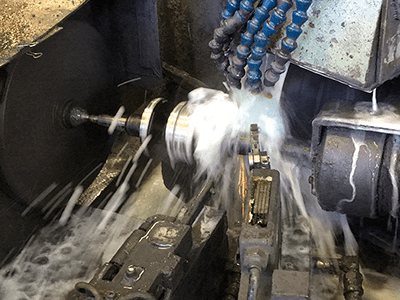

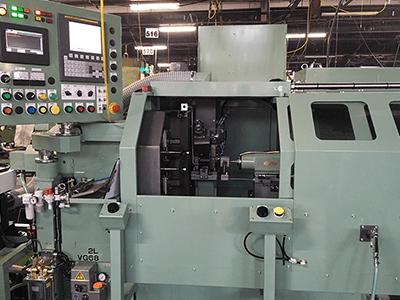

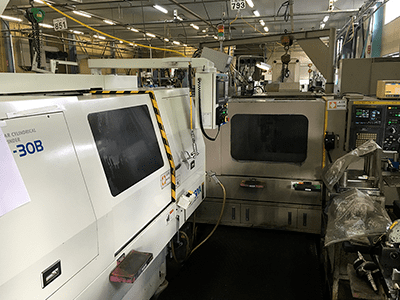

Grinding is a process to make the metallic surface smooth by whetstone. Other than using a whetstone, a film called paper-wrap is used for fine surface finish. By finishing the surface smoothly, friction can be reduced.

We do grinding for not only connecting rods and crankshafts, but also shafts used in air-conditioners as well.